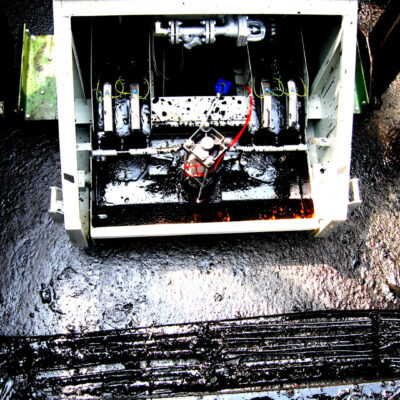

THE TAYLOR MADE OIL SKIMMER

Discoil, is the oil skimmer with discs that resolve various and multiple problems, even in situations with the risk of chemical corrosion (solvents, chloride), mechanical abrasion (sand, metal particles and abrasive materials) and critical temperature situations (due to the weather, cold or hot climates). The decision to diversify work, techniques and equipment is never standard but based on the needs that arise from the different types of problems. In fact, when the environment creates corrosive, abrasive and wear conditions that are the variables taken in the construction of a Discoil machine.

Oil flows into a primary collection tank (part of the machine) and then is transferred to a storage tank.

The transfer operation of the recovered product may be carried out using three main systems: