THE BEST OIL SKIMMER WITH DISCS, HYDRAULIC TYPE

O.C.S. OFFICINE COSTRUZIONI SPECIALI S.p.A. fabricates the oil skimmer DISCOIL, which has been invented in 1970 by the engineer Giancarlo Ravagnan. It has 50 years of experience and offers to its customers personalised solutions.

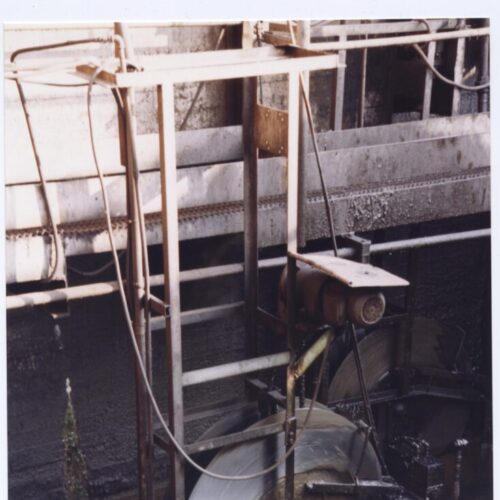

DISCOIL, patented by OCS, is an oil skimmer, hydraulic type, able to recover hydrocarbons by separation of insoluble floating oil on the surface of water.

The most frequent application is the separation of water from hydrocarbons (petrol, diesel, fuel oils, lubricating oils, crude oil, etc…) and fatty substances in general (animal and vegetable fats, etc…)

The operating principle is based on the adhesion of the oil to the surfaces of stainless steel discs which are arranged perpendicularly and partly immersed in the water, to be treated, while they are kept rotating on their horizontal axis. Molecular cohesion facilitates the recall of oily spots from a distance. As a result of this adhesion and cohesion, Discoil recovers oily products in their natural state at a considerable distance from the machine.

Another important OCS goal is product quality. It is fabricated with resistant materials that guarantee a long lifecycle, and the capability to work in many different and aggressive situations, including classified zones, working continuously 24h/day.